Key Advantages of Using a Membrane Switch in Industrial Applications

Key Advantages of Using a Membrane Switch in Industrial Applications

Blog Article

Recognizing the Functionality of Membrane Layer Switches for Interface Gadget

The performance of membrane layer switches represents a substantial innovation in interface layout, combining performance with aesthetic adaptability. These switches run via a multi-layered framework that equates customer interactions into electric signals, enabling both small layouts and strength versus ecological aspects. As markets progressively focus on individual experience, recognizing the nuances of membrane switch modern technology comes to be crucial. What implications do these improvements hold for future applications, and how might they redefine user interactions across numerous tools?

What Are Membrane Switches?

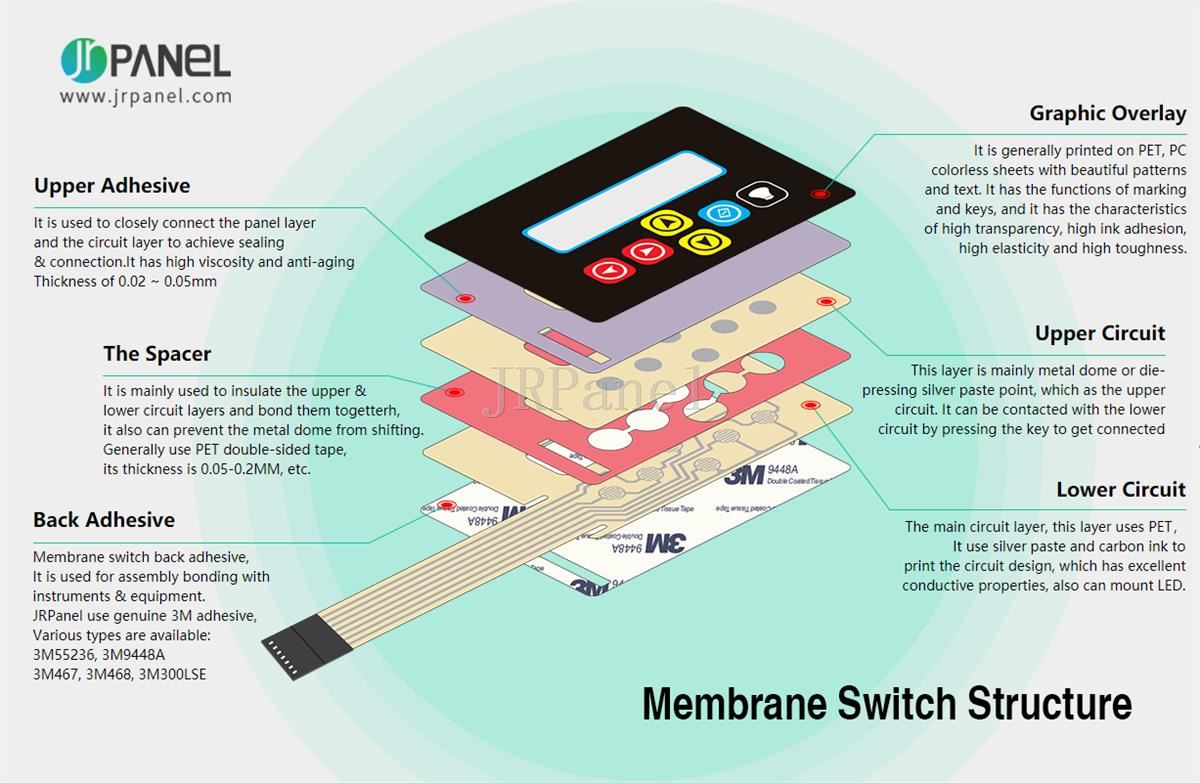

Membrane switches are ingenious interface gadgets that facilitate customer interaction with electronic tools. These flexible elements include several layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The style permits a smooth assimilation right into various digital devices, boosting both the aesthetic and practical aspects of customer interfaces.

Membrane layer switches are commonly utilized in a large range of applications, from home devices to commercial machinery and clinical gadgets. Their construction typically features a slim profile, making them an optimal selection for compact designs. The tactile feedback given by these buttons can be crafted to meet certain individual choices, ensuring effective communication between the user and the tool.

Sturdiness is one more significant benefit of membrane layer switches, as they are immune to dirt, dampness, and chemicals, which boosts their life-span popular environments. In addition, these buttons can be customized in regards to form, size, and visuals layout, permitting branding and user-specific attributes. Generally, membrane layer switches over stand for a sensible remedy for improving customer experience in electronic gadgets, combining functionality with aesthetic appeal in an effective fashion.

Just How Membrane Layer Switches Over Job

Operating on an uncomplicated principle, membrane changes use a layered building to register customer input effectively. Each button is composed of numerous layers, consisting of a printed circuit layer, a spacer layer, and a leading graphic layer, which are made to work together perfectly. When a user presses the top layer, it presses the spacer layer, bringing the conductive components of the circuit layer into call with each other.

This contact develops a closed circuit, indicating the device to implement a specific function. The layout allows for numerous configurations, including responsive responses, which can enhance the customer experience by supplying a physical experience upon activation. The materials used in membrane layer buttons typically consist of flexible substratums, such as polyester or polycarbonate, which ensure toughness and strength versus wear and tear.

Trick Advantages of Membrane Switches

An additional considerable advantage is their density. Membrane layer buttons are thin and light-weight, which makes it possible for makers to save room in their gadgets without giving up performance. This function is specifically valuable in applications where weight and volume are vital considerations.

Furthermore, membrane switches are immune to dust, dampness, and chemicals, improving their resilience. This strength extends their life-span and decreases the need for regular replacements, resulting in expense financial savings gradually.

Moreover, the tactile feedback given by membrane buttons can be optimized to improve customer interaction. They can include features such as increased switches or audible clicks, enhancing use and user experience.

Applications Throughout Industries

User interface tools utilizing membrane buttons are prevalent in a large array of industries, showcasing their versatility and capability. Membrane Switch. In the medical market, membrane layer buttons are essential to gadgets such as analysis tools and patient monitoring systems, where their durability and convenience of cleaning are important for keeping health criteria. In the automotive industry, these switches are employed in dashboard controls and infotainment systems, offering a smooth and contemporary user interface for customers.

In article addition, the customer electronic devices sector benefits from membrane layer buttons in devices and handheld gadgets, where small layout and easy to use interfaces improve customer experience. Industrial applications additionally leverage membrane switches over for control panels in machinery and automation systems, stressing their toughness and resistance to severe atmospheres.

In the aerospace and defense industries, membrane layer switches are used in cockpit controls and tools, where integrity and performance under extreme problems are extremely important. In addition, the video gaming market progressively includes membrane layer switches in controllers and arcade makers, adding to an appealing user experience. Overall, the convenience of membrane layer changes enables their prevalent usage across numerous markets, highlighting their relevance in modern-day individual interface design.

Future Patterns in Membrane Switch Innovation

Furthermore, the use of sophisticated materials, such as polycarbonate and polyester films, is expected to increase, giving enhanced toughness and resistance to ecological stress factors. These materials add to the total durability of membrane layer buttons, making them suitable for harsher commercial applications.

Moreover, the consolidation of wise innovation, consisting of IoT connection, will certainly make it possible for membrane buttons to connect with various other tools and systems, promoting a more interactive individual experience. This pattern straightens with the expanding need for clever tools throughout various industries, from health care to customer electronics.

Finally, customization alternatives are prepared for to increase, allowing manufacturers to create bespoke solutions tailored to particular individual requirements and preferences. These advancements will position membrane switches as essential components in the evolution of customer interface modern technology.

Final Thought

In verdict, membrane layer switches over represent a critical advancement in interface try this website innovation, providing a trustworthy and functional option for diverse digital applications. Their split building helps with compact layout, while functions such as responsive responses enhance customer interaction. The resilience against environmental factors additionally strengthens their utility throughout numerous markets. As improvements in product science and touch noticing modern technologies continue, the functionality and applicability of membrane layer buttons are expected to increase, enhancing their importance in contemporary electronic tools.

Report this page